Growth of photovoltaics

Between 1992 and 2023, the worldwide usage of photovoltaics (PV) increased exponentially. During this period, it evolved from a niche market of small-scale applications to a mainstream electricity source.[3] From 2016-2022 it has seen an annual capacity and production growth rate of around 26%- doubling approximately every three years.

When

Since the 1950s, when the first solar cells were commercially manufactured, there has been a succession of countries leading the world as the largest producer of electricity from solar photovoltaics. First it was the United States, then Japan,[7] followed by Germany, and currently China.

By the end of 2022, the global cumulative installed PV capacity reached about 1,185 gigawatts (GW), supplying over 6% of global electricity demand,[8] up from about 3% in 2019.[9] In 2022, solar PV contributed over 10% of the annual domestic consumption of electricity in nine countries, with Spain, Greece and Chile over 17%.[8]

Official agencies publish predictions of solar growth, often underestimating it.

Solar PV nameplate capacity

Wind power has different characteristics, e.g. a higher capacity factor and about four times the 2015 electricity production of solar power. Compared with wind power, photovoltaic power production correlates well with power consumption for air-conditioning in warm countries. As of 2017[update], a handful of utilities have started combining PV installations with battery banks, thus obtaining several hours of dispatchable generation to help mitigate problems associated with the duck curve after sunset.[19][20]

Current status

In 2022, the total global photovoltaic capacity increased by 228 GW, with a 24% growth year-on-year of new installations. As a result, the total global capacity exceeded 1,185 GW by the end of the year.[8]

Asia was the biggest installer of solar in 2022, with 60% of new capacity and 60% of total capacity. China alone amounted to over 40% of new solar and almost 40% of total capacity, but only 30% of generation.[21]

North America produced 16% of the world total, led by the United States. North America had the highest capacity factor of all continents in 2022 at 20%, ahead of South America (16%) and the world at large (14%).[21]

Almost all of the solar in Oceania (39TWh) was generated in Australia in 2022, in either case amounting to 3% of the world total. However, Oceania had the highest proportion of electricity that was solar in 2022 at 12%, ahead of Europe (4.9%), Asia (4.9%) and the world overall (4.6%).[21]

History of leading countries

The

United States (1954–1996)

The

In 1977 US-President

Japan (1997–2004)

Germany (2005–2014)

In 2005,

China (2015–present)

China surpassed Germany's capacity by the end of 2015, becoming the world's largest producer of photovoltaic power.[31] China's rapid PV growth continued in 2016 – with 34.2 GW of solar photovoltaics installed.[32] The quickly lowering feed in tariff rates[33] at the end of 2015 motivated many developers to secure tariff rates before mid-year 2016 – as they were anticipating further cuts (correctly so[34]). During the course of the year, China announced its goal of installing 100 GW during the next Chinese Five Year Economic Plan (2016–2020). China expected to spend ¥1 trillion ($145B) on solar construction[35] during that period. Much of China's PV capacity was built in the relatively less populated west of the country whereas the main centres of power consumption were in the east (such as Shanghai and Beijing).[36] Due to lack of adequate power transmission lines to carry the power from the solar power plants, China had to curtail its PV generated power.[36][37][38]

History of market development

This section needs to be updated. (March 2023) |

Prices and costs (1977–present)

| Type of cell or module | Price per Watt |

|---|---|

| Multi-Si Cell (≥18.6%) | $0.071 |

| Mono-Si Cell (≥20.0%) | $0.090 |

| G1 Mono-Si Cell (>21.7%) | $0.099 |

| M6 Mono-Si Cell (>21.7%) | $0.100 |

| 275W - 280W (60P) Module |

$0.176 |

| 325W - 330W (72P) Module | $0.188 |

| 305W - 310W Module | $0.240 |

| 315W - 320W Module | $0.190 |

| >325W - >385W Module | $0.200 |

| Source: EnergyTrend, price quotes, average prices, 13 July 2020[40] | |

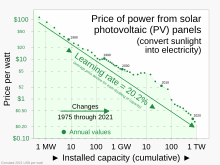

The average

This price trend was seen as evidence supporting

The followed figures for select countries represent the cost per kilowatt of utility-scale solar generation, as well as price per kilowatt-hour in 2022 and a comparison with 2010. Dollars are in 2022 international dollars. Data are from IRENA.[44]

| Country | $ / kW 2022 |

$ / kWh 2022 |

$/kWh 2010 |

% down |

|---|---|---|---|---|

| Australia | 923 | 0.041 | 0.453 | -91% |

| China | 715 | 0.037 | 0.331 | -89% |

| France | 1,157 | 0.062 | 0.423 | -85% |

| Germany | 996 | 0.080 | 0.401 | -80% |

| India | 640 | 0.037 | 0.376 | -90% |

| South Korea | 1,338 | 0.074 | 0.482 | -85% |

| Spain | 778 | 0.046 | 0.348 | -87% |

| United States | 1,119 | 0.058 | 0.235 | -75% |

Technologies (1990–present)

There were significant advances in conventional

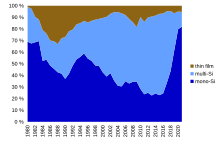

In 2013 thin-film technologies accounted for about 9 percent of worldwide deployment, while 91 percent was held by crystalline silicon (

- Copper indium gallium selenide (CIGS) is the name of the semiconductor material on which the technology is based. One of the largest conversion efficiencies of over 15%.[49] The company profited from the booming Japanese market and attempted to expand its international business. However, several prominent manufacturers could not keep up with the advances in conventional crystalline silicon technology. The company Solyndra ceased all business activity and filed for Chapter 11 bankruptcy in 2011, and Nanosolar, also a CIGS manufacturer, closed its doors in 2013. Although both companies produced CIGS solar cells, it has been pointed out, that the failure was not due to the technology but rather because of the companies themselves, using a flawed architecture, such as, for example, Solyndra's cylindrical substrates.[50]

- The U.S.-company AC Nyngan Solar Plant in Australia (the largest PV power station in the Southern Hemisphere at the time) commissioned in mid-2015.[51] The company was reported in 2013 to be successfully producing CdTe-panels with a steadily increasing efficiency and declining cost per watt.[52]: 18–19 CdTe was the lowest energy payback time of all mass-produced PV technologies, and could be as short as eight months in favorable locations.[48]: 31 The company Abound Solar, also a manufacturer of cadmium telluride modules, went bankrupt in 2012.[53]

- a-Si technology

- In 2012, Tokyo Electron Limited.[54][55] Other companies that left the amorphous silicon thin-film market include DuPont, BP, Flexcell, Inventux, Pramac, Schuco, Sencera, EPV Solar,[56] NovaSolar (formerly OptiSolar)[57] and Suntech Power that stopped manufacturing a-Si modules in 2010 to focus on crystalline silicon solar panels. In 2013, Suntech filed for bankruptcy in China.[58][59]

Silicon shortage (2005–2008)

In the early 2000s, prices for

However, there was a severe silicon shortage in 2005, when governmental programmes caused a 75% increase in the deployment of solar PV in Europe. In addition, the demand for silicon from semiconductor manufacturers was growing. Since the amount of silicon needed for semiconductors makes up a much smaller portion of production costs, semiconductor manufacturers were able to outbid solar companies for the available silicon in the market.[60]

Initially, the incumbent polysilicon producers were slow to respond to rising demand for solar applications, because of their painful experience with over-investment in the past. Silicon prices sharply rose to about $80 per kilogram, and reached as much as $400/kg for long-term contracts and spot prices. In 2007, the constraints on silicon became so severe that the solar industry was forced to idle about a quarter of its cell and module manufacturing capacity—an estimated 777 MW of the then available production capacity. The shortage also provided silicon specialists with both the cash and an incentive to develop new technologies and several new producers entered the market. Early responses from the solar industry focused on improvements in the recycling of silicon. When this potential was exhausted, companies have been taking a harder look at alternatives to the conventional

As it takes about three years to build a new polysilicon plant, the shortage continued until 2008. Prices for conventional solar cells remained constant or even rose slightly during the period of silicon shortage from 2005 to 2008. This is notably seen as a "shoulder" that sticks out in the Swanson's PV-learning curve and it was feared that a prolonged shortage could delay solar power becoming competitive with conventional energy prices without subsidies.

In the meantime the solar industry lowered the number of grams-per-watt by reducing wafer thickness and kerf loss, increasing yields in each manufacturing step, reducing module loss, and raising panel efficiency. Finally, the ramp up of polysilicon production alleviated worldwide markets from the scarcity of silicon in 2009 and subsequently lead to an overcapacity with sharply declining prices in the photovoltaic industry for the following years.

Solar overcapacity (2009–2013)

Graphs are unavailable due to technical issues. There is more info on

solar PV module production capacity in % since 1993[62] : 47 As the solar module prices and, as a consequence, many manufacturers could no longer cover costs or remain competitive. As worldwide growth of PV deployment continued, the gap between overcapacity and global demand was expected in 2014 to close in the next few years.[63]

IEA-PVPS published in 2014 historical data for the worldwide utilization of solar PV module production capacity that showed a slow return to normalization in manufacture in the years leading up to 2014. The utilization rate is the ratio of production capacities versus actual production output for a given year. A low of 49% was reached in 2007 and reflected the peak of the silicon shortage that idled a significant share of the module production capacity. As of 2013, the utilization rate had recovered somewhat and increased to 63%.[62]: 47 Anti-dumping duties (2012–present)After anti-dumping petition were filed and investigations carried out,[64] the United States imposed tariffs of 31 percent to 250 percent on solar products imported from China in 2012.[65] A year later, the EU also imposed definitive anti-dumping and anti-subsidy measures on imports of solar panels from China at an average of 47.7 percent for a two-year time span.[66] Shortly thereafter, China, in turn, levied duties on U.S. polysilicon imports, the feedstock for the production of solar cells. History of deployment Deployment figures on a global, regional and nationwide scale are well documented since the early 1990s. While worldwide photovoltaic capacity grew continuously, deployment figures by country were much more dynamic, as they depended strongly on national policies. A number of organizations release comprehensive reports on PV deployment on a yearly basis. They include annual and cumulative deployed PV watt-peak , a break-down by markets, as well as in-depth analysis and forecasts about future trends.

Growth by year100

200

300

400

500

2002

2006

2010

2014

2018

2023

Added capacity in gigawatts (hover with mouse over bar).   Reached grid-parity before 2014 Reached grid-parity after 2014 Reached grid-parity only for peak prices U.S. states poised to reach grid-parity Source: Deutsche Bank, as of February 2015 Number of countries with PV

Growing number of solar gigawatt-markets

Over 100 GW

Between 2000 and 2022, solar capacity increased by an average of 37% per year, doubling every 2.2 years. Over the same time period, the capacity factor increased from 10% to 14%. Data in the following table are from Ember, released in 2023,[21] with earlier data from BP released in 2014.[70]

See also

NotesReferences

External links

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||