Plastic recycling

Plastic recycling is the processing of

Almost all plastic is non-biodegradable and without recycling, spreads across the environment[7][8] where it can cause harm. For example, as of 2015 approximately 8 million tons of waste plastic enter the oceans annually, damaging the ecosystem and forming ocean garbage patches.[9] Even the highest quality recycling processes lead to substantial plastic waste during the sorting and cleaning process, releasing large amounts of microplastics in waste water, and dust from the process.[10][11]

Almost all recycling is mechanical: melting and reforming plastic into other items. This can cause

Plastic recycling is low in the waste hierarchy. It has been advocated since the early 1970s,[13] but due to economic and technical challenges, did not impact plastic waste to any significant extent until the late 1980s. The plastics industry has been criticised for lobbying for expansion of recycling programs, even while research showed that most plastic could not be economically recycled.[14][15][16]

History

Although

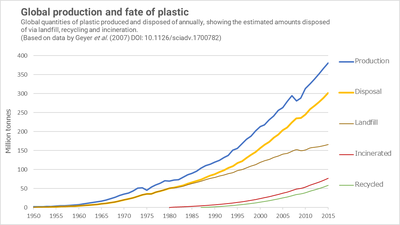

Global

Industry lobbying

As regulations expanded, the plastics industry responded with lobbying to preserve their business interests. In the U.S., the 1970 Resource Recovery Act directed the nation towards recycling and energy recovery.

However, plastic could not be economically recycled using the technology of the time. For example, an April 1973 report written by industry scientists stated that, "There is no recovery from obsolete products" and that, "A degradation of resin properties and performance occurs during the initial fabrication, through aging, and in any reclamation process." The report concluded that sorting the plastic is "infeasible". Contemporary scientific reports highlighted numerous technical barriers.[20][21][22][23][24]

Globally, plastic waste was almost entirely disposed of via landfill until the 1980s when rates of incineration increased. Although better technology was known,[25] these early incinerators often lacked advanced combustors or emission-control systems, leading to the release of dioxins and dioxin-like compounds.[26]

In the late 1980s plastic recycling began in earnest. In 1988 the U.S. Society of the Plastics Industry created the Council for Solid Waste Solutions as a trade association to promote the idea of plastic recycling to the public.[27] The association lobbied American municipalities to launch or expand plastic waste collection programs and lobbied U.S. states to require the labelling of plastic containers and products with recycling symbols.[14][15]

The industry introduced resin identification codes in 1988, which provided a standard system for the identification of various polymer types at materials recovery facilities.

Global recycling trade

Many governments count items as recycled if they have been exported for that purpose, regardless of the actual outcome. The practice has been labeled

In 2017, China began restricting waste plastics imports via Operation National Sword. Exporters eventually exported to other countries mostly in Southeast Asia, such as Vietnam and Malaysia, but also Turkey and India.[32][33] Indonesia, Malaysia, and Thailand reacted to illegal plastic waste imports by reinforcing border controls. Illegally imported containers were repatriated or refused entry. Consequently, plastic waste containers accumulated in ports.[31]

Given limited export options, attention turned to local solutions. Proposed extended producer responsibility would tax plastic producers to subsidise recyclers.[34]

In 2019, international trade in plastic waste became regulated under the Basel Convention. Under the convention, any Party can decide to prohibit imports of hazardous plastic waste and, since 1 January 2021, of some mixed plastic wastes. Parties to the convention are required to ensure environmentally sound management of their refuse either through alternative importers or by increasing capacity.[31]

The COVID-19 pandemic temporarily reduced trade in plastic waste, due in part to reduced activity at waste management facilities, shipping disruptions, and low oil prices that reduced the cost of virgin plastic and made recycling less profitable.[31]

European Union strategic developments

The European Commission's "Action Plan" for a circular economy, adopted in December 2015, saw plastics as a strategic priority for developing circular economy actions. In 2017, the Commission further adopted a focus on plastic production and use, targeting the achievement of all plastic packaging being recyclable by 2030. The Commission then issued a strategic document in January 2018 which set out an "ambitious vision" and an opportunity for global action on plastic recycling.[12]

Production and recycling rates

The total amount of plastic ever produced worldwide, until 2015, is estimated to be 8.3 billion tonnes.[6] Approximately 6.3 Bt of this was discarded as waste, of which around 79% accumulated in landfills or the natural environment, 12% was incinerated, and 9% was recycled - only ~1% of all plastic has been recycled more than once.[6] More recently, as of 2017, still only 9% of the 9 billion tonnes of plastic produced was recycled.[35][36]

By 2015 global production had reached some 381 Mt per year.[6] The recycling rate that year was 19.5%, while 25.5% was incinerated and the remaining 55% disposed of, largely to landfill. These rates lag behind those of other recyclables, such as paper, metal and glass. Although the percentage of recycled or incinerated material is increasing each year, the tonnage of waste left-over also continues to rise. Production could reach ~800 Mt per year by 2040, although implementing all feasible interventions could reduce plastic pollution by 40% from 2016 rates.[37]

Recycling rates vary among types of plastic. Several types are in common use, each with distinct chemical and physical properties. This affects sorting and reprocessing costs; which affects the value and market size for recovered materials.

One of the reasons for low levels of plastic recycling is weak demand, given the materials' poor/inconsistent properties.[12] The percentage of plastic that can be fully recycled, rather than downcycled or go to waste, can be increased when manufacturers minimise mixing of packaging materials and eliminate contaminants. The Association of Plastics Recyclers has issued a "Design Guide for Recyclability".[40]

The most commonly produced plastic consumer products include packaging made from LDPE (e.g. bags, containers, food packaging film), containers made from HDPE (e.g. milk bottles, shampoo bottles, ice cream tubs), and PET (e.g. bottles for water and other drinks). Together these products account for around 36% of plastic production. The use of plastics in building and construction, textiles, transportation and electrical equipment accounts for another substantial share of the plastics market.[41]

Regional data

Plastic consumption differs among countries and communities, although it is found almost everywhere. As of 2022 North American countries (

In 2012, 25.2 Mt of post-consumer plastic waste was collected in the European Union. Of this, more than 60% (15.6 Mt) was recovered and 40% (9.6 Mt) was disposed of as municipal solid waste (MSW). Of the 15.6 Mt of recovered plastic waste, about 6.6 Mt was recycled, while the remainder was likely used as refuse-derived fuel (RDF) or incinerated in MSW incinerators with energy recovery (about 9 Mt). Europe leads in plastics recycling, reusing about 26%.[42]

The recycling activities of the largest producers of plastic waste have the greatest effect on global averages. These are a mix of advanced economies and large developing nations. Some publish official statistics on their plastic recycling rates. Others may release partial data, usually limited to population centres. This makes it difficult to draw accurate comparisons, especially as the published recycling rates vary.

| Country | Plastic waste per year (Mt)[43] | Waste per person per day (Kg)[43] | Recycled | Incinerated (with energy recovery) | Landfill (and incineration without energy recovery) | Comments |

|---|---|---|---|---|---|---|

| China | 59.08 | 0.12 | - | - | - | No official statistics |

| United States[44] | 37.83 | 0.34 | 8% | 14% | 78% | Source: EPA |

| EU total*[45] | 24.7 | 0.15 | 24% | 34% | 42% | |

| Germany[45] | 14.48 | 0.48 | 33% | 65% | 2% | |

| Brazil | 11.85 | 0.17 | - | - | - | No official statistics |

| Japan[46] | 7.99 | 0.17 | 27% | 49% | 24% | |

| Pakistan | 6.41 | 0.10 | - | - | - | No official statistics |

| Nigeria | 5.96 | 0.10 | 12% | 0% | 88% | Estimated values |

| Russia | 5.84 | 0.11 | 6% | 0% | 94% | World bank estimates (2013)[47] |

| Turkey | 5.60 | 0.21 | 5% | 0% | 95% | Estimated values |

| Egypt | 5.46 | 0.18 | - | - | - | No official statistics |

| Indonesia | 5.05 | 0.06 | 19% | 0% | 81% | Estimated values |

| United Kingdom[45] | 4.93 | 0.21 | 23% | 8% | 69% | |

| Spain[45] | 4.71 | 0.28 | 23% | 17% | 60% | |

| France[45] | 4.56 | 0.19 | 18% | 40% | 42% | |

| India | 4.49 | 0.01 | 42% | 18% | 40% | Estimated values |

| Rest of World | 60.76 | - | - | - | - | No official statistics |

| World Total[6] | 245.00 | 0.10 | 16% | 22% | 62% |

* Although not formally a country, legislation affecting recycling is often made at the EU level

Identification codes

- Blue is widely recycled

- Yellow is sometimes recycled

- Red is usually not recycled

Many plastic items bear symbols identifying the type of

RICs are not mandatory in all countries, but many producers voluntarily mark their products. More than half of U.S. states have enacted laws that require plastic products be identifiable.

RICs are not particularly important for single-stream recycling, as these operations are increasingly automated. However, in some countries citizens are required to separate their plastic waste according to polymer type before collection. For instance, in Japan PET bottles are collected separately for recycling.

| Plastic identification code | Type of plastic polymer | Properties | Common applications | Melting- and glass transition temperatures (°C) | Young's modulus (GPa) |

|---|---|---|---|---|---|

|

Polyethylene terephthalate (PET) | Clarity, strength, toughness, barrier to gas and moisture | Soft drink, water and salad dressing bottles; peanut butter and jam jars; ice cream cone lids; small non-industrial electronics | Tm = 250;[52] Tg = 76[52] |

2–2.7[53] |

|

High-density polyethylene (HDPE) | Stiffness, strength, toughness, barrier to gas and moisture | Water pipes, gas and fire pipelines, electrical and communications conduits, five gallon buckets , milk, juice and water bottles, grocery bags, some toiletry bottles

|

Tm = 130;[54] Tg = −125[55] |

0.8[53] |

|

Polyvinyl chloride (PVC) | Versatility, ease of blending, strength, toughness. | blister packaging . Non-packaging uses include electrical cable insulation, rigid piping and vinyl records.

|

Tm = 240;[56] Tg = 85[56] |

2.4–4.1[57] |

|

Low-density polyethylene (LDPE) | Ease of processing; strength; flexibility; ease of sealing; moisture barrier. | Frozen food bags; squeezable bottles, e.g. honey, mustard; cling films; flexible container lids | Tm = 120;[58] Tg = −125[59] |

0.17–0.28[57] |

|

Polypropylene (PP) | Strength; resistance to heat, chemicals, grease and oil; moisture barrier. | Reusable microwaveable ware or take-away containers; kitchenware; yogurt or margarine containers; disposable cups and plates; soft drink bottle caps. | Tm = 173;[60] Tg = −10[60] |

1.5–2[53] |

|

Polystyrene (PS) | Versatility, clarity, easily formed, easily foamed | Egg cartons; disposable cups, plates, trays and cutlery; packing peanuts and package cushioning ;

|

Tm = 240 (only isotactic);[55] Tg = 100 (atactic and isotactic)[55] |

3–3.5[53] |

|

Other (often polycarbonate or ABS) | Dependent on polymers or combination of polymers | Beverage bottles, baby milk bottles. Non-packaging uses for polycarbonate: compact discs, "unbreakable" glazing, electronic apparatus housing, lenses (including sunglasses), instrument panels.[61] | Polycarbonate: Tm = 225[62] Tg = 145;[63] |

Polycarbonate: 2.6;[53] ABS plastics: 2.3[53] |

Waste composition

Plastic waste consists of various polymer types.

Graphs are unavailable due to technical issues. There is more info on Phabricator and on MediaWiki.org. |

| Polymer | Waste production (Mt) | Percentage of all plastic waste | Polymer type | Thermal character |

|---|---|---|---|---|

| High-density polyethylene (HDPE) | 64 | 19.8% | Polyolefin | Thermoplastic |

| Low-density polyethylene ( LDPE ) |

45 | 13.9% | Polyolefin | Thermoplastic |

| polypropylene (PP) | 62 | 19.1% | Polyolefin | Thermoplastic |

| Polystyrene (PS) | 19 | 5.9% | Unsaturated polyolefin | Thermoplastic |

| Polyvinyl chloride ( PVC ) |

17 | 5.3% | Halogenated | Thermoplastic |

| Polyethylene terephthalate (PET) | 35 | 10.8% | Condensation | Thermoplastic |

| Polyurethane (PUR) | 18 | 5.6% | Condensation | Thermoset[65] |

| PP&A fibers[66] | 51 | 15.7% | Condensation | Thermoplastic |

| All Others | 12 | 3.7% | Various | Varies |

| Total (excludes additives) | 324 | 100% | - | - |

Collecting and sorting

Recycling begins with the collection and sorting of waste. Curbside collection operates in many countries. Waste is sent to a materials recovery facility or MBT plant where the plastic is separated, cleaned and sorted for sale. Unsuitable materials are sent to a landfill or incinerator. These operations account for a large proportion of the financial and energy costs associated with recycling.

Sorting plastic is more complicated than other recyclable materials because it comes in a greater range of forms. For example, glass is separated into three streams (clear, green and amber), metals are usually either steel or aluminum and can be separated using magnets or

Six types of

Various sorting approaches and technologies have been developed.[1] They can be combined in various ways.[68] In practice no approach is 100% effective.[69][70][68] Sorting accuracy varies between recyclers, producing a market where products are poorly standardised. This inconsistency is another barrier to recycling.

Manual separation

Sorting by hand is the oldest and simplest method. In developing countries this may be done by waste pickers, while in a recycling center, workers pick items off a conveyor-belt. It requires low levels of technology and investment, but has high labor costs. Although many plastic items have identification codes workers rarely have time to look for them, so leaving problems of inefficiency and inconsistency. Even advanced facilities retain manual pickers to troubleshoot and correct sorting errors.[68] Working conditions can be unsanitary.[71]

Density separation

| Plastic Type | Density (g/cm3) |

| Polyvinyl chloride | 1.38-1.41 |

| Polyethylene terephthalate | 1.38-1.41 |

| Polystyrene | 1.04-1.08 |

| High-density polyethylene | 0.94-0.98 |

| Low-density polyethylene | 0.89–0.93 |

| Polypropylene | 0.85-0.92 |

| Polystyrene foam | 0.01-0.04 |

Plastics can be separated by exploiting differences in their densities. In this approach the plastic is first ground into flakes of a similar size, washed and subjected to

Electrostatic separation

In electrostatic separators, the triboelectric effect is used to charge plastic particles electrically; with different polymers charged to different extents. They are then blown through an electric field, which deflects them depending on their charge, directing them into appropriate collectors. As with density separation, the particles need to be dry, be uniform in size and shape.[77] Electrostatic separation can be complementary to density separation, allowing full separation of polymers,[78] albeit of mixed colours.

Sensor-based separation

This approach is largely automated and involves various sensors linked to a computer, which analyses items and directs them into appropriate chutes or belts.

Scrap

Plastic waste is either industrial scrap (sometimes referred to as post industrial resin) or consumer waste. Scrap is generated during production and is usually handled differently.[81] It can include flashings, trimmings, sprues and rejects. As it is collected at the point of manufacture it is clean, and of a known type and grade, and is valuable. As scrap is mostly privately traded, it is often not included in official statistics.[81]

Mechanical recycling

The majority of plastic waste is made of

Plastics are melted at anywhere between 150–320 °C (300–610 °F), depending on polymer type.

Many of these problems have technological solutions, though they bear a financial cost. Advanced

Closed-loop recycling

In closed-loop, or primary recycling, used plastic is endlessly recycled back into new items of the same quality and type. For instance, turning drinks bottles back into drinks bottles. It can be considered an example of a circular economy. The continual mechanical recycling of plastic without reduction in quality is challenging due to cumulative polymer degradation[93] and risk of contaminant build-up. In 2013 only 2% of plastic packaging was recycled in a closed loop.[94] Although closed-loop recycling has been investigated for many polymers,[93] to-date the only industrial success is with PET bottle recycling.[95] This is because polymer degradation in PET is often repairable. PET's polymer chains tend to cleave at their ester groups and the alcohol and carboxyl groups left by this can be joined back together by the use of chemical agents called chain extenders.[96] Pyromellitic dianhydride is one such compound.

Open-loop recycling

In open-loop recycling, also known as secondary recycling, or downcycling, the quality of the plastic is reduced each time it is recycled, so that the material eventually becomes unrecyclable. It is the most common type.[94] Recycling PET bottles into fleece or other fibres is a common example, and accounts for the majority of PET recycling.[97] Life-cycle assessment shows it to be of ecological benefit.[98][3][97] Recycling can displace demand for fresh plastic.[99] However, if it is used to produce items that would not otherwise have been made, then it is not displacing production and is of little or no benefit to the environment.

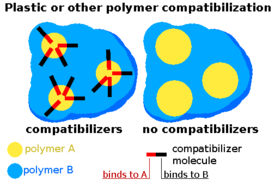

The reduction in polymer quality can be offset by mixing recycled and new materials. Compatibilised plastics can be used as a replacement for virgin material, as it is possible to produce them with the right melt flow index needed for good results.[100] Low quality mixed plastics can be recycled in an open-loop, although demand for such products is limited. When these are mixed during reprocessing the result is usually an unappealing dark-brown. These blends find use as outdoor furniture or plastic lumber. As the material is weak, but of low cost it is produced in thick planks to provide material strength.

Thermosets

Although

Feedstock recycling

In feedstock recycling, also called chemical recycling or tertiary recycling, polymers are reduced to their chemical building-blocks (

Thermal depolymerisation

Certain polymers like

Chemical depolymerisation

Energy recovery

Energy recovery, also called energy recycling or quaternary recycling, involves burning waste plastic in place of

Energy recovery is often the waste management method of last resort, a position previously held by landfill. In urban areas a lack of suitable sites for new landfills can drive this,

Plastic waste may be burnt as refuse-derived fuel (RDF), or it may be chemically converted to a synthetic fuel first. In either approach PVC must be excluded or compensated for by installing dechlorination technologies, as it generates large amounts of hydrogen chloride (HCl) when burnt. This can corrode equipment and cause undesirable chlorination of fuel products.[120] Burning has long been associated with the release of harmful dioxins and dioxin-like compounds, however these hazards can be abated by the use of advanced combustors and emission control systems. Incineration with energy recovery remains the most common method, with more advanced waste-to-fuel technologies such as pyrolysis hindered by technical and cost hurdles.[118][121]

Waste-to-fuel

Mixed plastic waste can be depolymerised to give a synthetic fuel. This has a higher

Compared to the widespread practise of incineration, plastic-to-fuel technologies have struggled to become economically viable.[123][134]

Other applications

Coke replacement

Many

Construction and concrete

The use of recovered plastics in engineering materials is gaining ground.

See also

- Economics of plastics processing

- Electronic waste

- Microplastics

- Mobro 4000

- Phase-out of lightweight plastic bags

- Plastics 2020 Challenge

Sources

![]() This article incorporates text from a free content work. Licensed under Cc BY-SA 3.0 IGO (license statement/permission). Text taken from Drowning in Plastics – Marine Litter and Plastic Waste Vital Graphics, United Nations Environment Programme.

This article incorporates text from a free content work. Licensed under Cc BY-SA 3.0 IGO (license statement/permission). Text taken from Drowning in Plastics – Marine Litter and Plastic Waste Vital Graphics, United Nations Environment Programme.

References

- ^ PMID 19577459.

- PMID 24811748.

- ^ .

- ^ PMID 19528059.

- .

- ^ PMID 28776036.

- .

- S2CID 3962436.

- S2CID 206562155.)

{{cite journal}}: CS1 maint: numeric names: authors list (link - ^ Paul, Andrew (8 May 2023). "Recycling plants spew a staggering amount of microplastics". Popular Science. Retrieved 8 May 2023.

- S2CID 258457895.

- ^ a b c Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions – A European Strategy for Plastics in a Circular Economy, COM(2018) 28 final, 6 January 2018

- ^ ISBN 978-1-4684-0873-7.

- ^ a b c National Public Radio, 12 September 2020 "How Big Oil Misled The Public Into Believing Plastic Would Be Recycled"

- ^ a b c PBS, Frontline, 31 March 2020, "Plastics Industry Insiders Reveal the Truth About Recycling"

- ^ Dharna Noor (15 February 2024). "'They lied': plastics producers deceived public about recycling, report reveals". theguardian.com. Retrieved 16 February 2024.

- NPR.org. Retrieved 15 June 2021.

- ISSN 0037-7791.

- JSTOR 41720628.

- .

- .

- .

- .

- .

- .

- .

- .

- ^ PMID 29938223.

- Greenpeace UK. Retrieved 20 May 2021.

- PMID 32603969.

- ^ a b c d Environment, U. N. (21 October 2021). "Drowning in Plastics – Marine Litter and Plastic Waste Vital Graphics". UNEP - UN Environment Programme. Retrieved 23 March 2022.

- S2CID 214271589.

- ^ "Piling Up: How China's Ban on Importing Waste Has Stalled Global Recycling". Yale E360. Retrieved 12 October 2020.

- S2CID 158295219.

- ^ "What Percentage of Plastic is Recycled Globally?". UCSB Bren School of Environmental Science & Management. Retrieved 22 January 2024.

- PMID 35066854.

- S2CID 221767531.

- ^ "Why plastic recycling is so confusing". BBC News. 18 December 2018. Retrieved 6 August 2021.

- ^ "Advancing Sustainable Materials Management: 2018 Tables and Figures" (PDF). US_EPA. Retrieved 9 November 2021.

- ^ "The Association of Plastics Recyclers | APR Design® Guide". The Association of Plastic Recyclers. Retrieved 24 February 2023.

- ^ a b Environment, U. N. (21 October 2021). "Drowning in Plastics – Marine Litter and Plastic Waste Vital Graphics". UNEP - UN Environment Programme. Retrieved 21 March 2022.

- ISBN 978-0-12-396459-5, retrieved 13 November 2022

- ^ a b Ritchie, Hannah; Roser, Max (1 September 2018). "Plastic Pollution". Our World in Data. Retrieved 22 September 2021.

- ^ US EPA, OLEM (12 September 2017). "Plastics: Material-Specific Data". www.epa.gov. Retrieved 22 September 2021.

- ^ a b c d e "Plastics facts 2011". www.plasticseurope.org. 2 June 2023.

- ^ "An Introduction to Plastic Recycling" (PDF). Plastic Waste Management Institute. Retrieved 22 September 2021.

- ^ "Waste in Russia: Garbage of valuable resource?". www.ifc.org.

- ^ a b "Standard Practice for Coding Plastic Manufactured Articles for Resin Identification". Standard Practice for Coding Plastic Manufactured Articles for Resin Identification. ASTM International. Retrieved 21 January 2016.

- ISBN 978-0-03-039114-9.

More than half the states in the United States have enacted laws that require plastic products to be labelled with numerical codes that identify the type of plastic used in them.

- ^ Official Journal of the EC; Commission Decision (97/129/EC) establishing the ID system for packaging materials pursuant to European Parliament & Council Directive 94/62/EC

- ^ Petsko, Emily (11 March 2020). "Recycling Myth of the Month: Those numbered symbols on single-use plastics do not mean 'you can recycle me'". Oceana. Retrieved 12 October 2020.

- ^ a b Scott, Chris. "poly(ethylene terephthalate) information and properties". PolymerProcessing.com. Retrieved 13 July 2017.

- ^ a b c d e f "Modulus of Elasticity or Young's Modulus – and Tensile Modulus for common Materials". EngineeringToolbox.com. Retrieved 13 July 2017.

- ^ "Dyna Lab Corp". DynaLabCorp.com. Archived from the original on 22 November 2010. Retrieved 13 July 2017.

- ^ a b c "Sigma Aldrich" (PDF). SigmaAldrich.com. Retrieved 13 July 2017.

- ^ a b Scott, Chris. "poly(vinyl chloride) information and properties". PolymerProcessing.com. Retrieved 13 July 2017.

- ^ a b Modern Plastics Encyclopedia 1999, p B158 to B216. (Tensile modulus)

- ^ "Dyna Lab Corp". DynaLabCorp.com. Archived from the original on 21 September 2011. Retrieved 13 July 2017.

- ^ "Wofford University". LaSalle.edu. Archived from the original on 11 January 2010. Retrieved 13 July 2017.

- ^ a b Scott, Chris. "polypropylene information and properties". PolymerProcessing.com. Retrieved 13 July 2017.

- ^ "What is Polycarbonate (PC)?".

- ^ Scott, Chris. "polycarbonate information and properties". PolymerProcessing.com. Retrieved 13 July 2017.

- ^ "polycarbonate information and properties". PolymerProcessing.com. 15 April 2001. Retrieved 27 October 2012.

- ^ ISBN 978-0-12-817880-5.

- ^ The majority of polyurethanes are thermosets, however some thermoplastics are also produced, for instance spandex

- synthetic fibres. Care should be taken not to confuse it with polyphthalamide(PPA)

- PMID 29035713.

- ^ .

- S2CID 198331405.

- PMID 33887695.

- PMID 7610383.

- hdl:10012/11956.

- ^ PMID 28823699.

- .

- S2CID 6670818.

- )

- S2CID 12323746.

- .

- PMID 27663707.

- .

- ^ ISSN 2211-3398.

- ^ PMID 33000883.

- .

- S2CID 209432804.

- .

- S2CID 54487823.

- .

- .

- .

- PMID 22575175.

- hdl:2268/4370.

- .

- ^ S2CID 199067235.

- ^ a b "The New Plastics Economy: Rethinking the future of plastics & catalysing action". www.ellenmacarthurfoundation.org. Retrieved 28 May 2021.

- .

- PMID 33000883.

- ^ .

- hdl:1854/LU-6851927.

- S2CID 153936564.

- PMID 35423365.

- .

- .

- S2CID 225247645.

- .

- S2CID 215760966.

- ^ PMID 32160372.

- ^ .

- .

- ^ "Plastics - the Facts 2020" (PDF). PlasticsEurope. Retrieved 1 September 2021.

- .

- S2CID 215411815.

- PMID 28371373.

- .

- .

- ^ "An Introduction to Plastic Recycling in Japan 2019" (PDF). Plastic Waste Management Institute. Retrieved 19 May 2021.

- ^ US EPA, OLEM (12 September 2017). "Plastics: Material-Specific Data". US EPA.

- ^ "Directive 2008/98/EC of the European Parliament and of the Council. Article 3: Definitions". Legislation.gov.uk. Paragraph 15a. 2008. Retrieved 4 August 2021.

{{cite web}}: CS1 maint: location (link) - ^ S2CID 209798113.

- S2CID 21744131.

- S2CID 94190060.

- PMID 28501263.

- .

- ^ S2CID 98550187.

- .

- .

- S2CID 201243993.

- .

- .

- .

- .

- S2CID 103779086.

- . Retrieved 10 June 2021.

- OSTI 1353191.

- S2CID 115296275.

- ^ "Scientists use plastic to make steel". CNN.com. Archived from the original on 12 August 2005. Retrieved 10 August 2005.

- S2CID 137233367.

- PMID 35591409.

- ISSN 0950-0618.

- ISSN 2075-5309.

- S2CID 212815459.

- ^ "Use of Plastic Waste in Road Construction".

- S2CID 234834344.

- PMID 33923013.

- ISSN 0950-0618.

- S2CID 219637371.