Portal:Clothing

The Clothing Portal

.

Clothing has significant social factors as well. Wearing clothes is a variable

social convention as the basis of customs. Clothing also may be used to communicate social status, wealth, group identity, and individualism. (Full article...

)

spacesuits, and doctor's gowns. (Full article...)

Textile arts are arts and crafts that use plant, animal, or synthetic fibers to construct practical or decorative objects. (Full article...)

Selected articles -

-

artificial fibres, and chemicals. It was established in 1794 and became the world's leading man-made fibre production company before being broken up in 1990 into Courtaulds plc and Courtaulds Textiles Ltd. (Full article...)

-

Harris Tweed industry as a means of livelihood for those who live in the Outer Hebrides of Scotland.)

The Harris Tweed Authority is responsible for safeguarding the standard and reputation of Harris Tweed, promoting awareness of the cloth internationally, and disseminating information about material falling within the definition of Harris Tweed and articles made from it. (Full article... -

Cloak, 1580–1600 V&A Museum no. 793–1901 Techniques – Red satin, couched and embroidered with silver, silver-gilt and coloured silk threads, trimmed with silver-gilt and silk thread fringe and tassel, and lined with pink linen

Aesthetics in textiles is one of the basic concepts of serviceability of textiles. It is determined by the perception of touch and sight. Aesthetics imply the appearance and attraction of textile products; it includes the color and texture of the material. It is a statement about the end user (consumer) and the target market. When combined with fabric construction, the finish of the clothing material, garment fit, style, and fashion compatibility, colours create an aesthetic comfort. All of these elements work together to satisfy our visual perception. Aesthetics incorporates the role of evaluation (analysing and judging) also.

There are various arts and applications that imparts aesthetic properties in textiles. Additionally, the use of LEDs and optical fibres enables the creation of aesthetic properties such as illuminated textiles. (Full article...) -

Did you know (auto generated)

- ... that during the Second World War, the British government's campaign Make-Do and Mendencouraged the public to fashion men's clothes into womenswear?

- ... that Liberian paramount chief Tamba Taylor worked as a tailor and claimed to have sewn clothes for Ethiopian emperor Haile Selassie and Ghanaian president Kwame Nkrumah?

- ... that Jacqueline Kennedy did not want to make her clothes the focus of her 1962 goodwill tour of India and Pakistan, but still wore 22 different outfits in the first nine days?

- ... that after being criticized for dressing "like a doll" at an important meeting, pioneering Russian feminist Anna Filosofova replied that "clothes do not make the woman"?

- ... that Church Clothes 4 deals with Christian hip hop artist Lecrae's faith deconstruction and reconstruction?

- ... that according to Brandy Hellville, executives at Brandy Melville have bought the clothes off of employees' backs?

More Did you know

- ...that dollars?

- ...that the Raphael Cartoons, tapestry designs from 1515 which are among the most influential works of Renaissance art, remained torn into strips for 175 years?

- ... that skins?

Related portals

Selected image

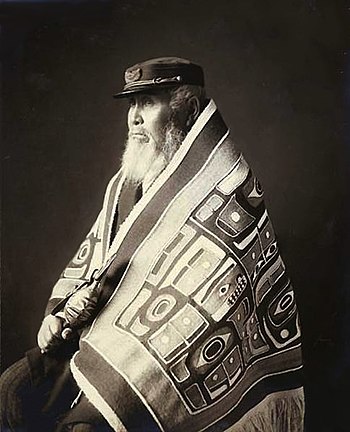

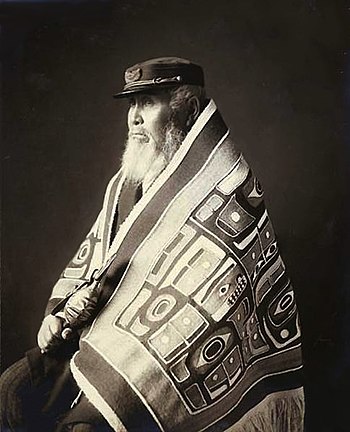

Chief Anotklosh (Taku) wearing a Chilkat blanket, Juneau, Alaska, ca. 1913 Chilkat weaving is a traditional form of weaving practiced by Tlingit, Haida, Tsimshian, and other Northwest coastal tribes of Alaska and British Columbia. Chilkat blankets are worn by high-ranking tribal members on civic or ceremonial occasions, including dances.

General images -

The following are images from various clothing-related articles on Wikipedia.-

Liu Wen, supermodel, walks the runway modeling fashions by designer Diane von Fürstenberg at New York Fashion Week 2013. (from Fashion)

-

Celebrities such as Britney Spears have popularized the concept of wearing underwear as outerwear. (from Fashion)

-

Edgar I of England in short tunic, hose, and cloak, 966 (from History of clothing and textiles)

-

Albrecht Dürer's drawing contrasts a well-turned out bourgeoise from Nuremberg (left) with her counterpart from Venice. The Venetian lady's high chopines make her look taller. (from Fashion)

-

Model with a modern dress reflecting the current fashion trend at a fashion show, Paris, 2011 (from Fashion)

-

Latin dancers in their costumes. The woman is wearing backless dress with deep slits on its lower portion, while the man is wearing a shirt with top buttons open. (from Fashion)

-

Woman's Bicycling Ensemble, 1898,LACMA (from Fashion)

-

Indigenous Americas Map Tunic designed in 2018 by Carla Fernández and Pedro Reyes for Taller Flora. (from Fashion)

-

Textile machinery at the Cambrian Factory, Llanwrtyd, Wales in the 1940s (from History of clothing and textiles)

-

Afashion trends get popularised through media. (from Fashion)

-

14th-century Italian silk damasks (from History of clothing and textiles)

-

Gensei Kajin Shu bytraditional Japanese clothing and Western styles. (from Fashion)

-

Marie Antoinette, wife of Louis XVI, was a leader of fashion. Her choices, such as this 1783 white muslin dress called a chemise a la Reine, were highly influential and widely worn. (from Fashion)

-

Bold floral patterned silks, 15th century (from History of clothing and textiles)

-

Tie dye vendor, July 2013 (from Fashion)

-

Cover ofMarcus Clarks' spring and summer catalogue 1926–27 (from Fashion)

-

Minidress by John Bates, 1965 (from Fashion)

-

The Boxer Codex, showing the attire of a Classical period Filipino, made of silk and cotton (from History of clothing and textiles)

-

Gross sales of goods vs IP laws (US 2007) (from Fashion)

-

A French reinterpretation of Spanish fashion, with elaborate reticella ruff, 1609 (from History of clothing and textiles)

-

Bella Hadid at the Cannes Film Festival (from Fashion)

-

Kaia Gerber at the 2019 Max Mara Fashion Week in Milan (from Fashion)

-

"Swinging London": Young adults in London's Carnaby Street. (from Fashion)

-

This 1921 clipping from the St. Louis Post-Dispatch, with story and drawings by Marguerite Martyn, represents the saturation newspaper coverage given to society women at a fashionable dance. (from Fashion)

-

A woman inBengal region in the eastern part of the Indian subcontinent, clad in fine Bengali muslin, 18th century. (from History of clothing and textiles)

-

Estonian national clothes are a fine example of change in clothing after the industrial revolution. They changed a lot during 18th and 19th of century with the addition of new types of colors (like aniline dyes), placement of colors (like lengthwise stripes) and with the addition of new elements (like waistcoats). By the end of the 19th century they went out of use in most of the country (except more remote places as in Kihnu island) and it was only in mid 20th century when they once again gained popularity and now as a formal clothing. Members of University of Tartu Folk Art Ensemble wearing clothes specific to Kihnu island, Tori Parish (women in red skirts) and Tõstamaa area (men in brown clothing). (from History of clothing and textiles)

-

Jacqueline Kennedy, the wife of President John F. Kennedy, made pink a popular high-fashion color. (from Fashion)

-

A Mexican sports reporter Inés Sainz wearing a little black dress and knee-high boots (from Fashion)

-

Timberland boots are an everyday shoe in streetwear. (from Fashion)

Selected quote

Main topics

Recognized content

Extended content

This is a list of recognized content, updated weekly by WP:RECOGfor configuration options.Featured articles

Good articles

Featured pictures

-

17.17-37-1969-Kaukasisk-broderi

-

17th century Central Tibeten thanka of Guhyasamaja Akshobhyavajra, Rubin Museum of Art

-

Eugène Grasset - A La Place Clichy

-

Khalili Collections A Composite Imaginary View of Japan

Featured portals

Subcategories

WikiProjects

- Parent project

- Main project

- Participants

- Related projects

WikiProject Fashion • WikiProject Knots • WikiProject Sculpture • WikiProject Visual arts

What are WikiProjects?

Things you can do

Here are some tasks awaiting attention:- Elongated stitch (knitting), More stubs...

- Verify : Clothing, Ply, Bobbinet, Braid, Canvas, Cardigan (sweater), Cotton-spinning machinery, Crocheted lace, Damask, Distaff, Dobby loom, Drawn thread work, Dyeing, Hemline, Ikat, Lace, Natural fiber, Neckline, Oilskin, Overlock, Machine embroidery

- Other : Help find and upload Requested pictures

- Place the {{WikiProject Textile Arts}} project banner on the talk pages of all articles within the scope of the project.

- Place the {{Portal|Textile arts}} portal template in the See alsosection of associated articles.

- Improve a top priority textile arts article.

- Original research removal: Clothing, History of knitting

Associated Wikimedia

The following Wikimedia Foundation sister projects provide more on this subject:

-

Commons

Free media repository -

Wikibooks

Free textbooks and manuals -

Wikidata

Free knowledge base -

Wikinews

Free-content news -

Wikiquote

Collection of quotations -

Wikisource

Free-content library -

Wikiversity

Free learning tools -

Wiktionary

Dictionary and thesaurus

Discover Wikipedia using portals

- ... that during the Second World War, the British government's campaign